Inductors are passive devices used in electronic circuits to store energy in the form of a magnetic field. They are the compliment of capacitors, which store energy in the form of an electric field. Inductors come in a variety of forms, but they each play an important role in the workings of electronic devices. They are available for high-power applications, noise suppression, radio frequency, signals, and isolation.

Erocore's main products are:

(1) SMD Power Inductor (Shielded / Unshielded)

(2) Common Mode Choke & Coil

(3) Wire Wound Chip Coil

(4) Multilayer Chip Bead

(5) RF Inductor

(6) Torodial Inductor

(7) EMI Ferrite Core

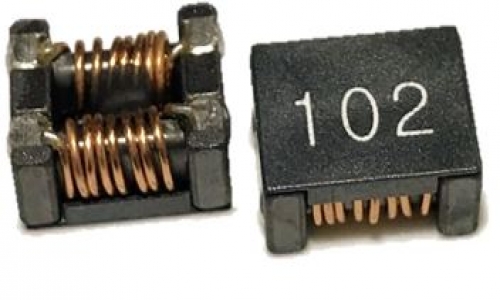

1. SMD Power Inductors(Shielded / Unshielded):

Power Inductor is one of the common-used electrical passive components which usually come along with capacitors. The main applications are like DC-DC Converters, Switching Power Module, UPS, Voltage Regulator,etc. Power Inductors also come in many types such as Shielded type, Unshielded type, Resin-shielded type, Molding type.

Multilayer inductors get their name from the layers of coiled wire that are wound around a central core. Adding additional layers of coiled wire to an inductor increases the inductance, but it also increases the capacitance between the wires. These inductors trade off higher inductance for a lower maximum operating frequency.

Multilayer chip bead that is for EMI protection , Low DC resistance, high soldering heat resistance , muliple size availability for all kind of 4C applications, various electronics euqipments.

3. Molding High Current Power Inductors:

Inductors that are molded into a plastic or ceramic housing are known as molded inductors. Generally, these inductors have a cylindrical or bar form factor, and they can be found with several types of winding options. Erocore provides Molded type high current power inductors which can be used for general & automotive application. Erocore MPF Series is directly cross to Coilcraft XAL Series which is flat wire coil that achieve ultra high current for next generation of power supply units.

Power inductors are available in a wide variety of form factors and power levels. They include everything from surface mount inductors that can handle a few amps to through-hole and chassis mount power inductors that can handle tens to hundreds of amps. Because power inductors are subjected to large amounts of current, they tend to generate large magnetic fields. To prevent these magnetic fields from inducing noise in other parts of the circuit, magnetically shielded inductors should be used if possible.

High-frequency inductors, also called radio frequency (RF) inductors, are designed to operate at high frequencies. These inductors often have a higher resistance and lower current rating. Most RF inductors have an air core rather than a ferrite or other inductance-boosting core material. This is because the increase in losses when those core materials are used reduce the operating frequency of the inductor.

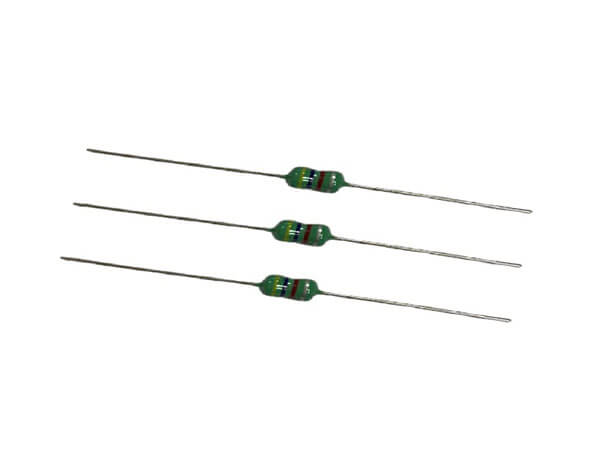

Similar to Axial Inductors, Radial Inductors are wounded on cylindrical bobbin so these are named as bobbin based inductors. These are mainly used for mounting on printed circuit boards.It consist of two types of leads they are axial lead and radial lead. Axial lead means lead exits from both sides of the core for horizontal mounting on PC board. Radial lead means lead exits from both sides of the core for vertical mounting on PC board. For Radial Inductor with embossment, it can achieve high value of inductance and low DCR which is suitable for SMPS Circuit, Imput and output filter & PI Filter.

This form of inductor is wound on a toroid - a circular former. Ferrite is often used as the former as this increases the permeability of the core. The advantage of a toroid is that the toroid enables the magnetic flux to travel in a circle around the toroid and as a result the flux leakage is very low. The disadvantage with a toroidal inductor is that it requires a special winding machine is required to perform the manufacture as the wire has to be passed thought the toroid for each turn required. The main application of Toroidal Core Inductor is Medical Devices, Switching Regulators, Industrial Controllers & Output Filters(SMPS)